Views: 0 Author: Site Editor Publish Time: 2025-05-13 Origin: Site

If you're considering investing in a direct drive motor, one of your top questions might be: How long will it last? The answer depends on several factors including usage patterns, environmental conditions, motor design, and maintenance routines. But generally speaking, direct drive motors are known for their impressive durability and extended operational lifespans, especially when compared to conventional motors that rely on belts, pulleys, or gearboxes.

Let’s take a deep dive into what determines the lifespan of a direct drive motor, how you can extend it, and what benefits our motors provide for industrial and commercial applications.

A high-quality direct drive motor can easily last over 30,000 to 50,000 hours, and in ideal conditions, it may exceed 100,000 hours of operation. That’s more than a decade of daily usage, assuming average duty cycles. Unlike brushed motors or gear-driven systems, direct drive motors are not prone to mechanical wear from intermediate parts, which significantly boosts their service life.

| Motor Type | Typical Lifespan | Key Factors in Wear |

|---|---|---|

| Brushed DC Motor | 2,000 – 5,000 hours | Brush/commutator wear |

| Gear Motor | 5,000 – 20,000 hours | Gear fatigue, lubricant loss |

| Direct Drive Motor | 30,000 – 100,000+ hours | Bearing degradation, insulation aging |

Industrial grade motors: 8–15 years of continuous duty

HVAC and appliance-grade motors: 10–12 years in domestic conditions

Precision robotics: 5–8 years under high load and accuracy demands

Direct drive motors eliminate many common failure points. No gears to wear out, no belts to snap, and minimal vibration. This leads to:

Lower heat generation

Less friction-related degradation

Fewer moving parts that require replacement

Fewer mechanical interfaces: Direct coupling means reduced wear

High torque at low RPMs: Reduced need for speed-reduction gears

Smooth acceleration: Less strain on motor windings and bearings

It’s not just the design that determines how long your direct drive motor will last—real-world conditions play a big role too. Here are the major factors:

Running the motor near its rated torque and speed will optimize its longevity. Operating under overload can reduce lifespan significantly.

Heat, dust, moisture, and vibration can all cause early degradation if not controlled. Make sure your setup includes proper ventilation and enclosure ratings.

Motors that frequently start and stop or run under cyclic loads tend to wear faster than those running at a steady rate.

Although direct drive motors have fewer components, the bearings still undergo wear over time. Using magnetic or air bearings can reduce this.

Using sophisticated controllers that support smooth acceleration, torque control, and overload protection will extend service life.

Want your investment to go the distance? These tips will help you extend the lifespan of your direct drive motor:

✅ Keep motor temperature under control using thermal sensors and heat sinks.

✅ Lubricate or replace bearings according to the manufacturer's recommendations.

✅ Protect the motor from power surges with proper circuit protection.

✅ Align the motor and load accurately to avoid axial load on the shaft.

✅ Avoid continuous operation at the absolute max ratings.

| Task | Frequency | Benefit |

|---|---|---|

| Clean motor vents | Monthly | Prevents overheating |

| Inspect bearings | Quarterly | Reduces vibration and noise |

| Check alignment | Bi-annually | Prevents wear from load shifts |

| Review controller logs | Monthly | Detects overload or errors |

| Test insulation resistance | Annually | Prevents electrical failure |

Even the best direct drive motor will show signs of wear eventually. Here’s what to watch for:

Increased operating temperature

Vibration or abnormal noise

Drop in torque output

Excessive current draw

Loss of position accuracy (in servo systems)

As industries move toward high-efficiency, low-maintenance machinery, the demand for direct drive motors is booming. From industrial automation to electric vehicles, these motors are becoming the backbone of motion systems.

Emerging trends include:

Integrated diagnostics: Smart motors with real-time health monitoring

Magnetically-levitated rotors: Virtually friction-free performance

AI-driven predictive maintenance: Extend lifespan through intelligent scheduling

Compact, frameless designs: Seamless embedding in robotic joints or medical tools

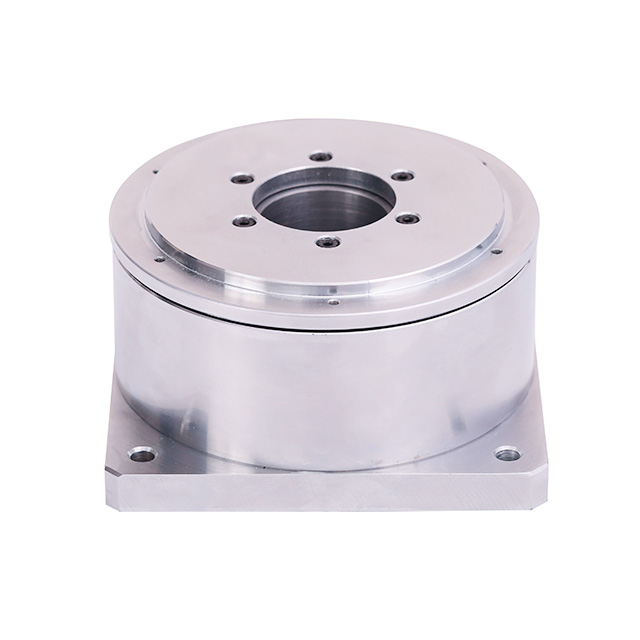

At Direct-Drive-Motor.com, we engineer motors that are built for endurance. Our frameless torque motors and sealed integrated systems offer unmatched durability, with optimized cooling and bearing support structures.

Our Product Advantages:

Custom-wound stators for high efficiency

Corrosion-resistant housings

IP-rated enclosures for demanding environments

Dynamic balancing for ultra-quiet performance

Q1: Do direct drive motors last longer than servo motors?

A: In many cases, yes. The lack of gear reduction means fewer parts to wear out. Servo motors often rely on mechanical gearboxes that can fail earlier than the motor itself.

Q2: Can direct drive motors be used 24/7?

A: Absolutely. Provided they’re within rated specifications and cooled properly, these motors are ideal for continuous operation.

Q3: What causes most failures in direct drive motors?

A: Bearing wear and insulation breakdown. Both can be minimized with regular inspections and correct motor sizing.

Q4: How does temperature affect motor lifespan?

A: Every 10°C rise above rated temperature can halve the insulation life. Keeping motors cool is key to long service life.

Q5: Are direct drive motors repairable?

A: Yes, especially if caught early. Bearings, windings, and encoders can often be serviced or replaced to restore functionality.

A direct drive motor offers more than just performance—it’s a long-term solution for precision, reliability, and reduced maintenance. Whether you’re upgrading factory automation, developing a robotic system, or powering next-gen medical devices, the right motor can be the difference between constant repairs and years of smooth operation.

For industry-grade solutions designed to last, visit www.direct-drive-motor.com and connect with our experts today.