Views: 0 Author: Site Editor Publish Time: 2025-05-16 Origin: Site

Energy efficiency determines how effectively a motor converts electrical power into mechanical work. Let's explore how direct drive motors compare with gear-driven systems in real-world settings.

Gear motors contain several moving parts that cause energy loss through:

Friction in gear teeth

Lubrication drag

Vibration and noise

In contrast, direct drive motors eliminate most of these losses by removing the intermediate drivetrain entirely.

| Feature | Direct Drive Motor | Gear Motor |

|---|---|---|

| Gear friction | None | High |

| Heat generation | Low | Moderate to High |

| Mechanical complexity | Minimal | Complex |

| Energy transfer rate | Very high | Moderate |

Heat is one of the major contributors to energy loss. Direct drive motors are naturally more thermally efficient because they generate less internal friction. Gearboxes, on the other hand, can get hot under load and require cooling or ventilation systems, which consume additional energy.

While gear motors are often used to match torque and speed, direct drive motors are now capable of achieving similar torque levels using advanced winding techniques and stronger magnets. Additionally, modern controllers allow for precise speed control without the need for gears.

One practical example is in electric bicycles, where the debate between geared hub motors and direct drive hub motors is ongoing. Efficiency tests in real-world riding conditions reveal that:

Geared motors are efficient at low speeds and on hills but suffer from mechanical drag.

Direct drive motors are more efficient on flat terrain and at high speeds because of zero internal friction.

This makes direct drive motor systems ideal for commuter e-bikes that prioritize smooth, consistent power delivery and long-term reliability.

In large ventilation systems, direct drive motors are increasingly replacing belt-and-gear assemblies due to:

Reduced energy loss (estimated 15–20% gain in fan systems)

Lower maintenance costs

More responsive airflow control

Because there's no slippage or belt loss, more of the motor’s power goes directly into moving air. Plus, system designers can better predict airflow performance based on input power.

Noise and vibration are not just comfort issues—they're signs of wasted energy. Gear motors tend to be noisier due to gear engagement and backlash. Direct drive motors run quieter, and lower vibration means less energy is lost as heat or mechanical noise.

| Application | Direct Drive (dB) | Gear Motor (dB) |

|---|---|---|

| HVAC Fan System | 50–55 | 65–70 |

| Electric Bike at Cruise | 40–45 | 60+ |

Maintenance may not directly impact energy efficiency, but it affects overall system downtime and power usage. Direct drive motors have fewer moving parts, meaning:

No gear lubrication schedules

No belt replacement

Less chance of misalignment

This ensures that the motor performs consistently at peak efficiency for a longer period.

With the rise of Industry 4.0, direct drive motor technology is evolving to include:

Integrated sensors for torque, temperature, and speed

Self-diagnosing controllers

Real-time performance optimization

These smart systems reduce energy consumption by dynamically adjusting to workload and ambient conditions, something traditional gear motors can't do without add-ons.

Despite the energy efficiency edge of direct drive motors, gear motors are still useful when:

Space constraints require a compact high-torque setup

Low-speed high-torque is needed without high-end electronic control

Cost sensitivity outweighs long-term operational efficiency

But in most applications where performance, uptime, and efficiency are critical, direct drive motors are the better investment.

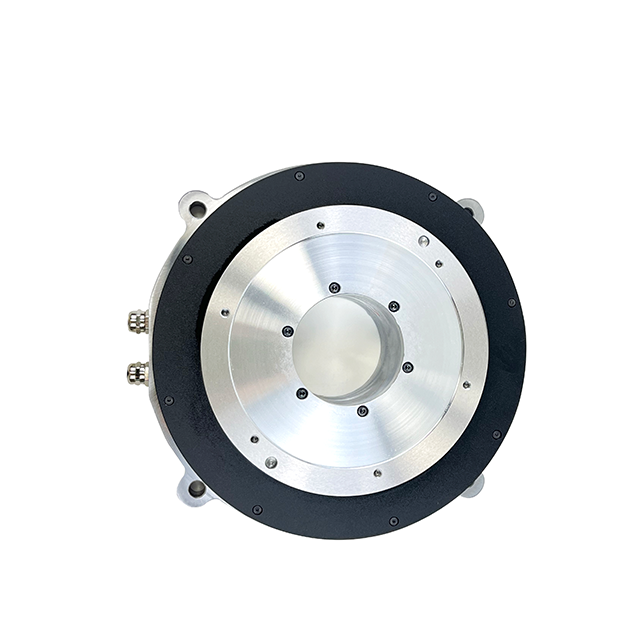

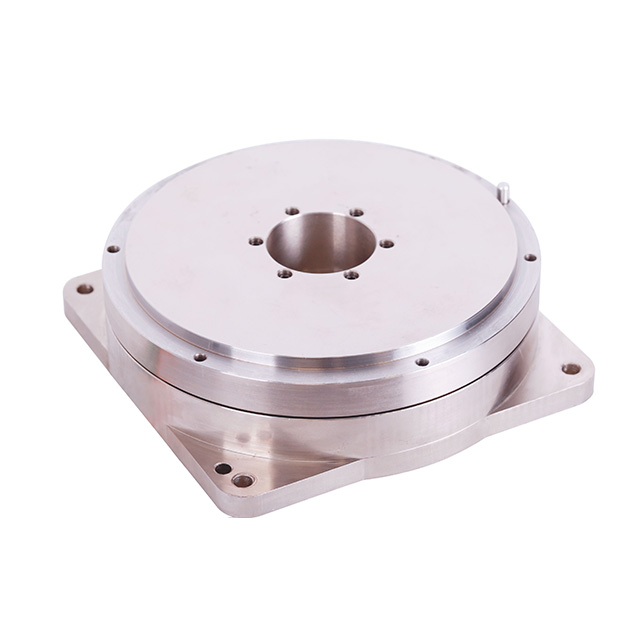

At Direct-Drive-Motor.com, our motors are engineered to maximize efficiency and durability. Our designs feature:

High-performance magnetic materials

Integrated thermal control

Frameless options for custom assemblies

Low-loss windings and ultra-precise tolerances

Q1: Which motor consumes less energy under similar load?

A: Direct drive motors, due to the elimination of mechanical losses from gearboxes and better thermal efficiency.

Q2: Is it worth replacing a gear motor with a direct drive motor?

A: Yes, especially in systems running 24/7 or where efficiency and maintenance matter. The initial upgrade cost is offset by lower energy bills and less downtime.

Q3: Can direct drive motors work in high-torque scenarios?

A: Absolutely. Modern motors can now deliver high torque at low speeds using larger stators and precision control systems.

Q4: Do direct drive motors require inverters or special controls?

A: They typically need advanced motor controllers, but these allow for better performance tuning and efficiency gains.

Q5: What industries benefit most from this efficiency?

A: HVAC, robotics, electric transportation, food processing, and precision manufacturing are top beneficiaries.

Whether you’re upgrading an industrial line or building a better e-bike, energy efficiency should be your guiding principle. With their superior mechanical design, low maintenance, and ability to work smarter—not harder—direct drive motors offer a clear path to better performance and sustainability.

To find the most efficient, durable, and application-specific direct drive motor, visit Direct-Drive-Motor.com and speak to our engineering team today.